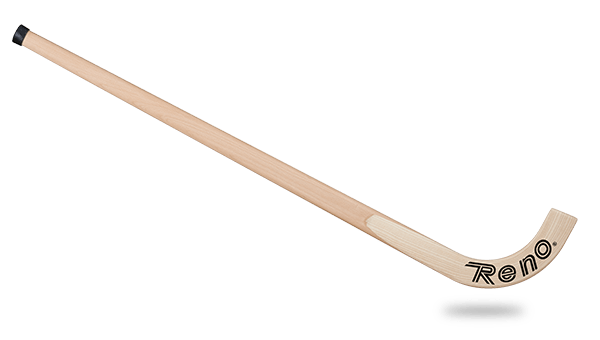

STICKS HANDCRAFTED, SINCE 1946

Reno has been handcrafting roller hockey sticks since 1946, at their factory in Cerdanyola del Vallès, very close to Barcelona. Recognized for their excellent touch and balance, Reno sticks help hockey players from around the world to give their best on the field.

Ash and beech

Each Reno stick is manufactured following a laborious artisanal process.

Our manufacturing method, which has remained virtually unchanged since 1946, consists of combining two different types of wood: Northern European ash wood – used for the blade due to its characteristic elasticity that allows it to be curved – and beech wood – used for the handle, because it has a very clean grain, knot-free, and very resistant.

Our process makes us unique

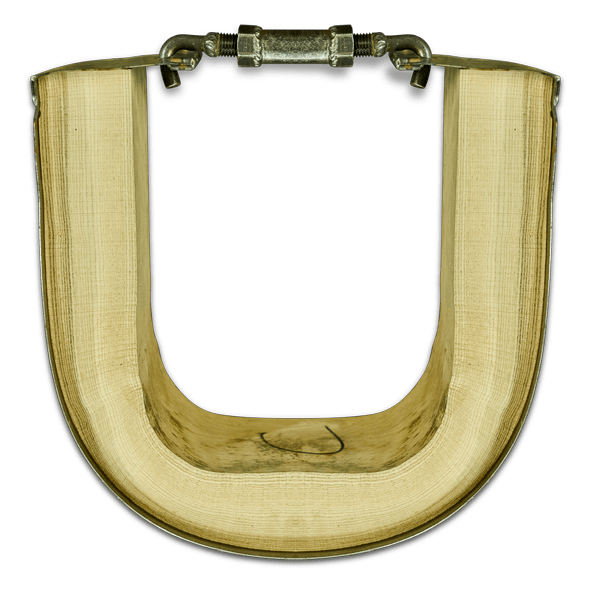

The manufacturing process of a Reno stick begins in special charcoal boilers, where the ash wood is subjected to a steam bath that allows bending it and giving it the characteristic shape of the blade.

Always flexible, never weak

After bending it, the blade is constructed by joining two pieces of wood and placing inside it a vulcanized fiber core, which functions to absorb impacts inherent to the game. Once constructed, it is attached to the handle and the entire assembly is machined using a CNC machine and a manual polishing process until the stick is obtained.

The stick is then finished by receiving a treatment to seal the wood porosities, and finally, the graphic image is applied, either through screen printing or digital printing.

Feeling the game

The artisanal manufacturing process of each Reno stick aims to achieve the extraordinary qualities provided by wood: transmitting the touch of the game better than any other material.

controlling the ball.

All Reno sticks undergo rigorous quality control to ensure that the product is in perfect condition and meets the characteristics that make our brand the favorite of the best hockey players worldwide.

Reno’s production center in Fiães, Portugal, manufactures all our boots and protections.

In addition to Reno sticks, we also produce hockey boots, player protections – gloves and knee pads -, goalie protections – leg guards, goalie gloves, chest protectors, etc. – and other textile materials related to the practice of hockey.